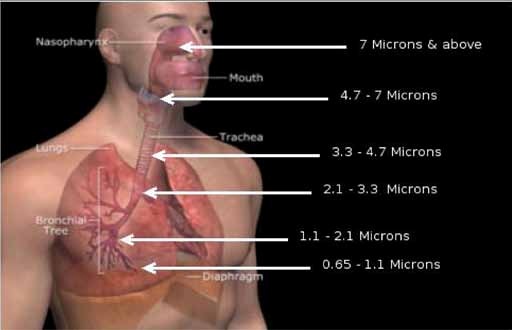

Emissions of fine particulate matter (PM and ultrafines) in diesel exhaust have been of growing community, industry and government concern. Their combination of extremely small size and chemical composition increases the likelihood that particles will carry irritants and toxic compounds into the deepest and most sensitive areas of the lungs.

This can lead to severe bronchial problems and increased susceptibility to respiratory infection, such as pneumonia, bronchitis, and asthma. Carbon soot particles from diesel engines adsorb onto their surfaces other metals and toxic substances produced by diesel engines such as cancer-causing aldehydes (like formaldehyde) and polycyclic aromatic hydrocarbons (PAH). Occupational health studies link cancers, particularly lung cancer to diesel exhaust exposures. Traffic studies suggest increased rates of respiratory and cardiovascular disease and risk of premature death near busy urban streets or highways and thus must be addressed by industry and government. This also places at high risk the health of the underground mine worker.

Until recently, practical, low cost equipment was not available to reliably monitor PM emissions other than the opacity meter. However, research has shown that there is not always a good correlation between visible smoke and emissions of fine particles, which are generally so small as to be invisible to the human eye.

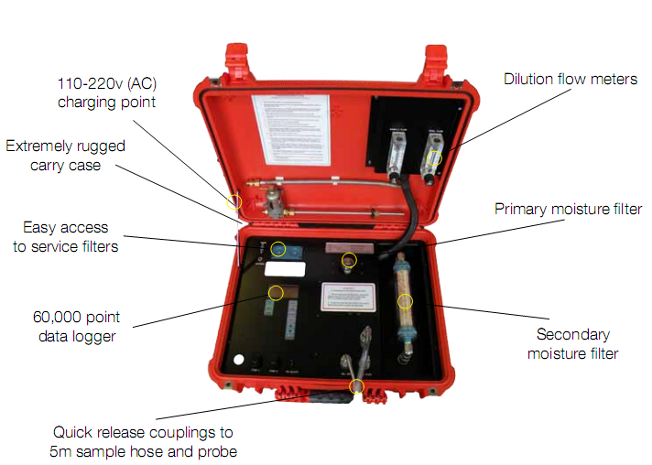

Recognising the need for a simple, rugged instrument to fulfill this need, Emitech has developed a real-time PM measuring instrument specifically designed to operate in the dirty, high PM concentration conditions found in diesel engine exhaust. This stand-alone laser-based PM instrument is battery powered, extremely portable and provides an immediate measurement of diesel exhaust PM concentration. The instrument has been proved after several years of measuring diesel exhaust gases in the underground coal mining environment.

The diesel exhaust gas sample contains large numbers of condensing water droplets especially after passing through water scrubbers. This must be removed prior to passing through the laser analyser in order to avoid incorrect readings arising from reflection and refraction of the laser beam by the water droplets. Even in underground hard rock mining where water scrubbers aren’t used, the exhaust gas holds moisture that requires the use of the dehumidifier. The Emitech LLSP-M-03 analyser was developed specifically for underground mining applications, and incorporates an integrated micro-dilution system and a proprietary water droplet separation system.

The Emitech instrument provides:

- second-by-second measurement of exhaust PM concentration (mg/m³)

- immediate display of results

- integrated data logging capabilities for storing results of multiple tests,

- data reporting and analysis

- battery operation for use in remote areas

- ability to measure ambient PM levels as well as exhaust PM concentration

- rugged packaging in a military-spec submersible case

- one-person operation

- results stored in the data logger can be downloaded to PC

- factory calibrated to correspond specifically with the properties of PM in diesel exhaust

- 0.01 to 1500mg/m³ concentration range.

The laser-based PM measuring system in the Emitech instrument does not suffer from the limitations of traditional measurement technologies. Because the instrument responds to optical signals processed in real-time, it provides a continuous stream of measurement data.

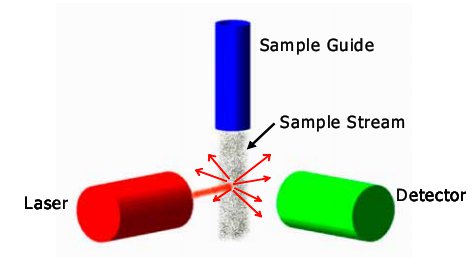

The following diagram illustrates the basic principles of a laser light-scattering system.

A sample of the exhaust stream is directed through a suitable guide into a measurement chamber, where a laser beam aimed into the stream is scattered by reflection and refraction when it strikes particles in the exhaust sample. A highly sensitive detector, positioned at a precise angle facing the illuminated zone, converts the incident scattered laser light into minute electrical signals. These signals are then amplified and processed by the instrument’s electronics to generate an output signal.

Laser light-scattering PM systems developed by Emitech have been extensively trialed in a number of government, university and independent agency test programs, using both on-road vehicles and mining engines. This work has demonstrated a strong correlation with the traditional filter method. The Emitech PM analyser also correlates well with established laboratory techniques such as the tapered element oscillating microbalance (TEOM) and aerodynamic particle sizer (APS).

To obtain a true performance comparison, for all the tests summarised in the chart, both the laser system and the laboratory’s certification-grade filter system drew their respective samples, in parallel, from the same sample stream over the same time period. Emitech’s laser PM measuring correlates extremely well with the certification-grade filter mass measurements, over a wide range of vehicle types.

The Emitech instrument can be used with any test procedure (idle, stall, transient, steady state, etc) however has proved to be the only method for measuring and evaluating performance of diesel particulate filters installed on earthmoving and mining vehicles in the underground environment.